Identifying and Solving Business Problems

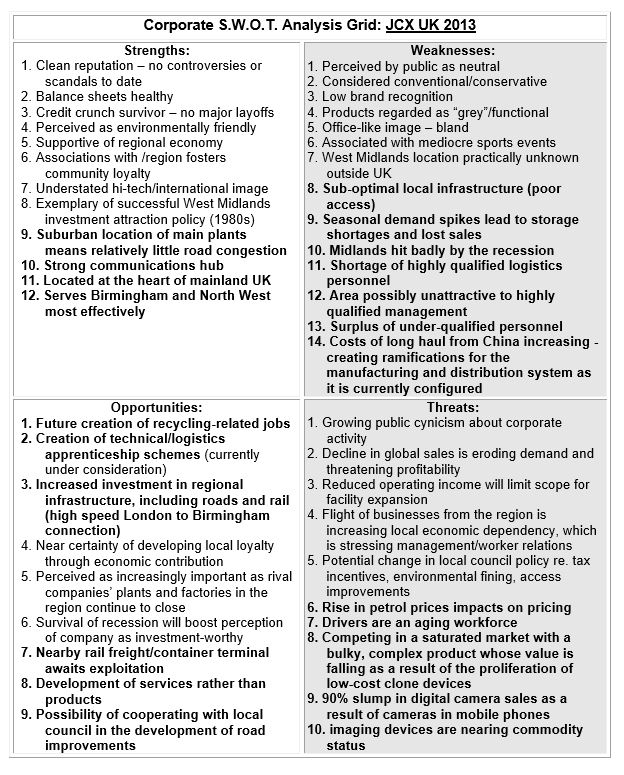

The SWOT is a useful – if sometimes not fully understood – tool for identifying a company’s current and relative (not long-term or absolute) strengths and weaknesses. Done competently, a SWOT analysis can help develop strategy. However, the efficacy of a SWOT is often degraded by the biases of the author or the quality of the data available to the author. The following example is based on a Japanese company’s UK operations division and concentrates on logistical considerations.

Using this, specific measures can be taken to address weaknesses – with KPIs and budgets ideally factored accordingly. Without the foregoing analysis, improvement measures maybe imprecisely applied and resources may not be allocated to where their contribution can be used to support or return to efficiency. A SWOT is effective only if its information generates focussed corrective or competitivity-driving activities. If multiple, separable activities are revealed by the SWOT as necessary, such activities could be managed as projects. Something like the following will result from an effective SWOT.

Areas Requiring Urgent Attention and Why

- Sales/marketing: printing and imaging devices are rapidly falling to commodity status. The market is dominated by the largest makers (Hewlett Packard). Some means of differentiation is required if market share is to be increased. The current recession conditions are highly contributory.

- Logistics 1. Systems: inward and outward; national and EU-wide. The current system is inventory heavy. This allows economies of scale in the shipping phase of the chain, but incurs high cost at the inventory storage (warehousing) phase. Dispatch by road to customers directly or to retail outlets describes the current mode. While workable, this mode is suboptimal. Dead stock and processing of returns erodes the benefits of centralized storage, despite the large inventory providing a very high degree of agility in terms of availability of items and efficiency of order expediting and despatch (especially in the case of national outward-bound goods).

- Logistics 2. Returns: Processing returns in the Midlands is unprofitable. Return-paid boxes and envelopes are possibilities for domestic and small office customers, but business customers require vehicles for the collection of larger products. Collection is normally handled by a courier (TNT), but at high cost to all parties. Disaggregation (disassembly) of products inside the UK is prohibitively costly. Thus, items are shipped to China for disaggregation and, if possible, salvage of parts and reinjection of recovered good components into the supply chain. However, items are not checked in the UK before they are despatched to China. The cause of their faults is not verified, which prompts the possibility that many items are replaced needlessly but at high cost. Lack of minor parts and components is also a deficiency. If such parts available were available, more items could be repaired and installed locally. At the moment, only major, limited lifespan components are stocked – and even these unprofitably. Such items are imaging units, toner bottles, rollers, and ink/toner cartridges.

- Logistics 3. Cost of securing goods in transit. Both modular and finished items are only partially trackable while in the system. Inward and outward-bound goods are exposed to the threat of breakage, accidental loss, intentional loss (theft), and inventory/dispatch error. RFID tagging of items of high value is a possible solution, but the issue of which party would bear the costs of the implementation is problematic.