Analysing Logistics 4: Identifying Causation

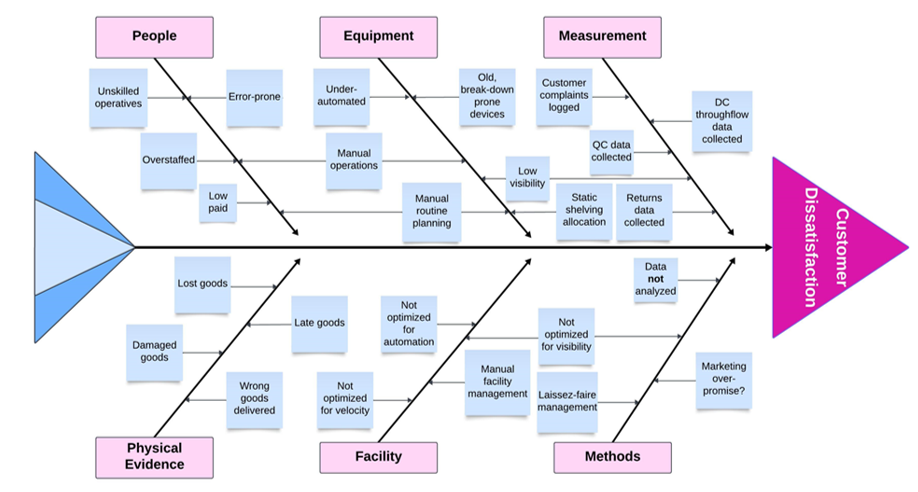

The Ishikawa/fishbone diagram diagramming method exposes the contribution of particular causes to a significant negative effect (Cadle et al., 2021). Once identified, the causes can be systematically addressed, negating the final identified result, i.e. customer dissatisfaction.

From this, we see that:

- By inference, all causes of risk/failure appear resolvable by a common method: technological upgrading. This fits our deduction (based on the UML diagram) that manual operations are responsible for/contribute to order failure.

- Customer dissatisfaction results from logistical inefficiencies, over all.

- The system evidences its malfunctioning in the form of wrong and late/early goods.

- The main categories of causation – People, Equipment, Measurement, Methods, and Facility – are strongly linked.