Analysing Logistics 3: System Modelling in More Detail

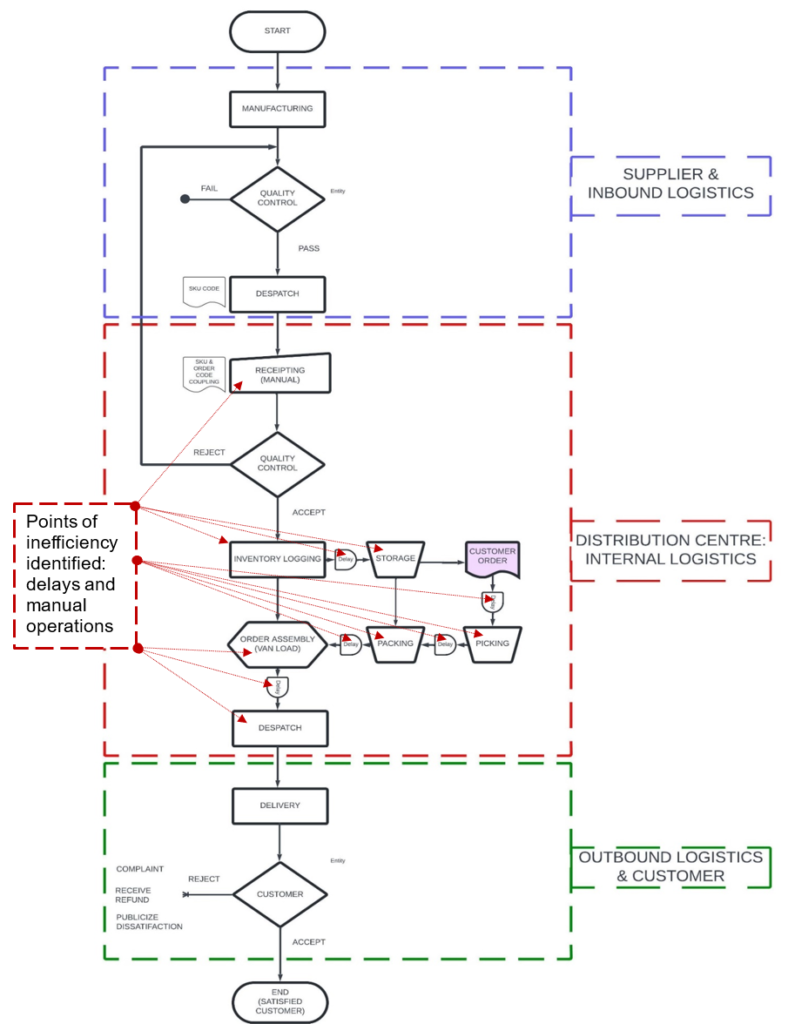

Paul and Cadle (2020) recommend UML as a method of depicting business processes for the purpose of defining requirements and identifying points of improvement. We can use the standard UML diagramming protocol to put more details into our system model.

Systems thinking facilitates systems performance, ergo system modelling should evidence systems thinking. We can depict this using a verbal logic model/system model. System modelling is recommended for identifying efficiency constraints in business processes,

In this case, the FNS logistics process is the business process of interest. In operations flows, and in supply chain configurations, modelling leads intuitively to analysis. Using the UML protocol (and some non-protocol callouts for extra clarity), the figure below reveals the constituent operations inside the three-phase logistics flow and thereby highlights points of potential delay and decision.

This depiction of the system reveals that many DC operations are manual. Therefore, order failures not attributable to outbound logistics are likely attributable to manual operations inside the DC.

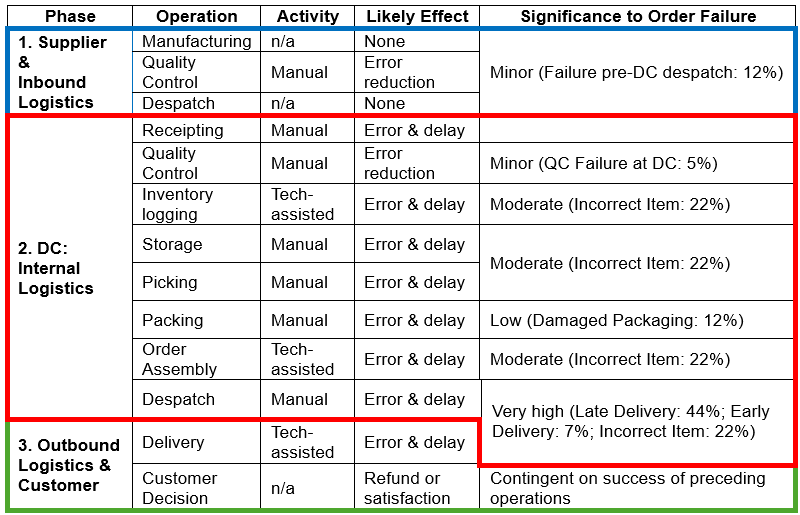

From an analysis of this diagram, the contribution of each operation/event to order failure can be supposed (see the following table). These links are based on the premise that manual operations are more prone to error and delay than automated operations – a premise generally supported by the literature.

Converting to automated processes should result in higher throughput and fewer errors, addressing all the reasons for order failure as reported by customers. This possibility can be explored by a cause-and-effect diagramming method.