Performance Significance of Supply Chain Configuration

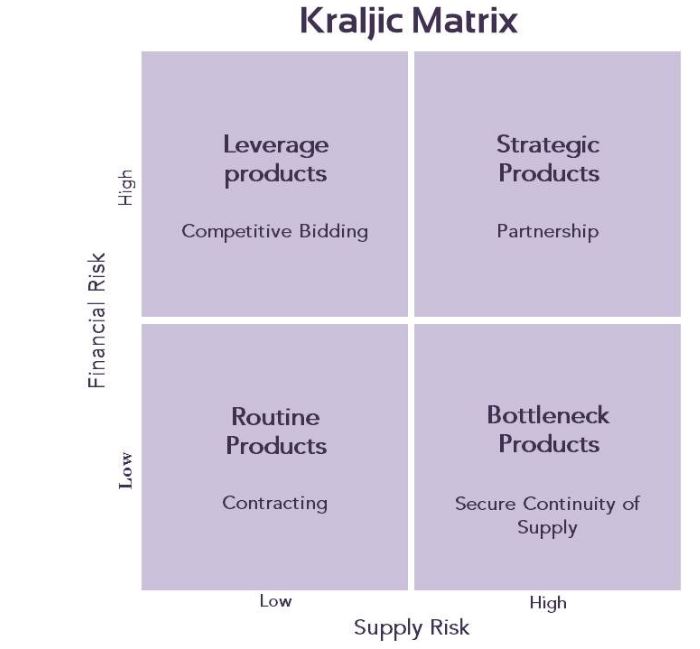

A Kraljik Matrix will likely be useful. The matrix, informed by the previous diagrams, will show the relative criticality and risk represented by items/classifications of supply under the current procurement/supply management scheme. Centralized procurement will likely provide the strongest economies of scale. Local procurement may however provide particular and attractive local advantages, but incur coordination complexity and erode group-wide procurement economies. The close coupling of DB with its suppliers will reduce internal logistics risk and possibly general commitment discounts, and other collateral economies.

Use of KPIs by the buyer (DB) will incentivise strong performance on the part of suppliers; long-term commitment (subject to formal KPI satisfaction) on the part of DB will encourage suppliers to invest in R&D and share expertise with DB. Mutual visibility of relevant data – supplier’s stock levels, locomotive performance – should also amplify the efficiencies of both parties and, ideally, generate economies that could feed into price reduction or less resourced DB SR activities.

Concerning traction supply, new procurement should focus on proven-reliable, diesel locomotives – such as the Class 66, which is heavily used by DB Schenker UK – since these offer the greatest transcontinental utility. Not restricted to electrified routes, diesels offer improved flexibility over electric traction with, in most cases, comparable performance (loads of unusually high weight will require the use of locomotives that provide highest tractive effort). Use of aging locomotives acquired in takeovers (e.g. EWS) should continue as long as their maintenance and performance remain practically and economically rational. If however multiple classes of locomotive necessitate involvement with high numbers of suppliers, the time/costs of coordination should be considered in addition to purely logistical costs (fuelling, running, and maintaining).

Where possible, supplier rationalisation should be practiced. That is, a single supplier capable of performing multiple activities, and ideally proven good and known to DB management, is managed more economically than multiple suppliers performing single activities, even if proven good and known to DB management.